Food To Go

Ogden Water have installed the first stage of a multi-part effluent treatment installation for a major UK manufacturer of sandwiches and food-to-go, which is a prominent supplier to national supermarkets.

The main issue on first consultation with site was the pH of the effluent being discharged to sewer. The local water company were growing increasingly concerned, with results outside of consent, therefore pH correction was prioritised.

The first part of the installed system includes:

- Two heavy duty feed pumps from the initial effluent reception sump, capable of 50m3/hr each.

- A pH correction tank with 24/7 agitation.

- pH monitoring and 4-20mA chemical dosing for pH correction.

- A buffering tank with level control for discharge.

- Two heavy duty discharge pumps to redirect effluent back towards sewer.

- Chemical supply.

- Monthly service visits.

As space on site is at a premium, the main pH correction equipment and tanks all had to be custom-built to fit within a 20ft shipping container, which would make the installation more discreet on site.

With the pH correction working well, the next stage of the installation will include:

- Permanent chemical storage tanks to replace IBCs and reduce chemical handling.

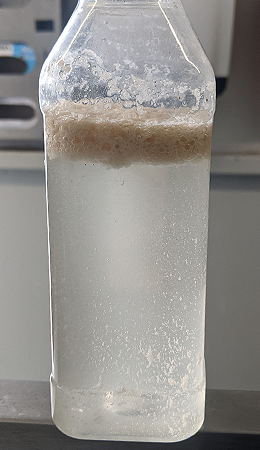

- Pre-treatment filtration - due to the nature of the business, there are many gross solids present in the effluent which have the potential to cause damage to equipment and pumps further down the line.