Speciality Bakery Products

Ogden Water were responsible for the design, manufacture and installation of a full waste water treatment plant for a leading speciality bakery manufacturer which produces a wide range of cakes, bread and bakery snack products for major UK retailers.

The site also benefits from treatment chemical supply and monthly service visits, which include the sampling and analysis of the waste water both before and after treatment, examination and inspection of equipment, recommendations for optimisation and advice on how to maximise efficiency with the treatment plant as a whole.

The plant is highly automated and features:

- Primary filtration using a rotary drum screen

- Balance tank

- Chemical dosing and mixing

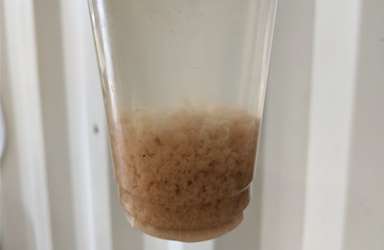

- Dissolved Air Flotation (DAF)

Due to the nature of the business, the untreated effluent typically contains high levels of solids, fats, oils and greases and the treatment plant corrects pH, removes solids and reduces settled Chemical Oxygen Demand (COD) levels all to within the specifications set by the water authority.

Total suspended solids are reduced from ~4500mg/L in the raw effluent to less than 100mg/L in the treated water to discharge. COD levels are down from ~9500mg/L in the raw effluent to ~1900mg/L in the treated water.

The plant currently processes 150-200m3 of effluent per day and sees savings of up to £1000 per day purely on disposal costs to the local water authority.